EVOTEK Filter Quality System

Focusing on consistent quality, we do not just pay attention to fulfill the requirements of the ISO 9001:2008 standards for our quality management system. The EVOTEK filter quality system covers the complete process from filter development up to shipping the finished product.

In the initial phase – either when choosing a filter or developing a filter matching the specific system and application which it will have to protect – there are several factors that have to be known to make the right choice. The viscosity of the fluid, working pressure, flow rate and the filtration requirements of the system are some of these variables. With these parameters our technical team determines a suitable filter media for the protection of the application as well as the housing matching the working pressure of the system.

Quality requirements and tests during the stage of development and filter choice

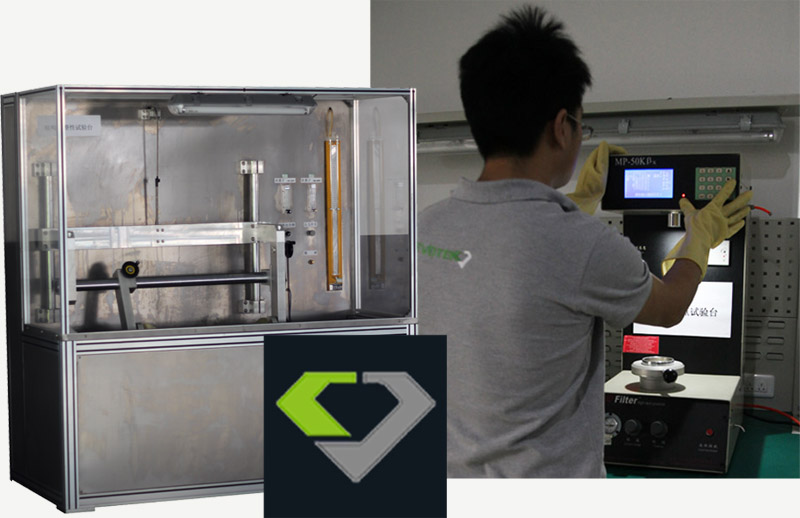

The filter media is the porous material in the filter element and responsible for the actual filtration process of the hydraulic fluid. Determined by the cleanliness level of the fluid, the choice is made between wire mesh, cellulose and fiber glass. We pay special attention to the quality of the fiber glass media used in our filters and have its performance tested by an internationally renowned specialist for filtration using the multi-pass test method in accordance with the ISO 16889 standard.)

The right balance between filtration efficiency, average differential pressure and a high Dirt Holding Capacity guarantees a long service life of our filter elements. Securing a constant quality level of our filter elements, we test each new batch of filtration media for constant values in bubble point and pore size. Furthermore a sample quantity of our running element production is tested for its fabrication integrity according to ISO 2942 standard to assure the stability of our production process and that no drop of fluid passes our filter contaminated.

The filter housing – containing the filter element – is designed in-house by our engineers using modern 3D software. Depending on its requirements towards pressure resistance and flow rate, it is manufactured out of a choice of high quality plastic, aluminium or iron casting parts. A pressure test according to ISO 2944 standard exposing the housing to three times the designed operating pressure validates the safety of the filter housing during operation.

In order to confirm the flow rate which the filter has been designed for, the flow characteristics (differential pressure vs. flow rate) of the filter element as well as the assembly with housing are being checked according to ISO 3968 standard. The resulting pressure drop graphs are used to draw conclusions about the optimal filter size for your application. Moreover, bypass valves are tested for opening pressure, leakage and flow characteristics.

EVOTEK filters have to pass 100% leakage tests after assembly.